Hammer Mill

Hammer Mill

>> Simple structure

>> High reduction ration

>> Easy operation and maintenance

>> Low investment

>> High manganese or high chrome hammers for option

>> Suitable for small scale grinding

Description

Crushing by the collisions between high-speed hammers and materials, the hammer mill were developed for both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and petroleum & chemical industries.

The hammer mill can be equipped with motor engine or diesel engine as per requirement.

Structure

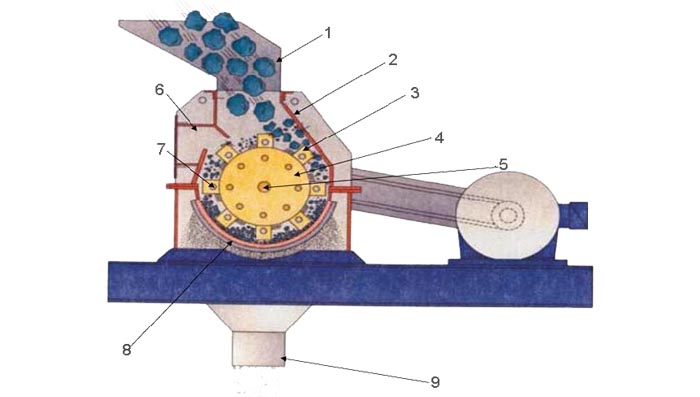

The hammer mill is mainly consist of frame, rotor, hammers, and other parts:

1. Feeding chute 2. Impact plate 3. Hammer 4. Rotor disc 5. Shaft 6. Metal trap

7. Hammer rod 8. Screen 9. Discharging port

Working Principle

1. Material is fed into the mill’s chamber typically by gravity.

2. The material is struck by ganged hammers which are attached to a shaft which rotates at a high speed inside the chamber. The materials are crushed or shattered by the repeated hammer impacts, collisions with the walls of the grinding chamber as well as particle on particle impacts.

3. Perforated metal screens, or bar grates covering the discharge opening of the mill retaining coarse materials for further grinding while allowing qualified sized materials to pass through as finished product.

Technical Specification

a

Contact Us

|

Name: Sabrina Huang

|

|

Skype: sabrina88196

|

|

|

Tel: 0086-15879777833

|

|

| Email: jinshibaosabrina@shakingtable.com.cn |

- Previous:Ball Mill

- Next:Hammer Crusher

Follow Us in LinkedIn

Follow Us in Youtube

Follow Us in Facebook

Address: No.9 Industrial Avenue of Guzhang Industrial Park, Shicheng County, Ganzhou City, Jiangxi Province, China

Tel:+86-797-5793186 Fax:+86-797-5793558 mobile phone:+86-13870712983

赣公网安备36073502000186

赣公网安备36073502000186