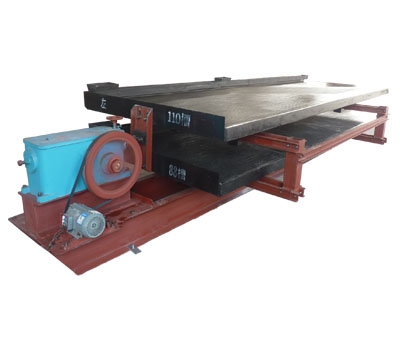

2-Deck Shaking Table

Double Deck Shaking Table

Click here to watch the video on Youtube

>> Smaller floor area.

>> Lower energy consumption.

>> A larger capacity.

>> High cost-performance.

>> Lower labor cost.

Description of shaking table

6-S shaking table is one gravity mining machine, which derives from spiral chute. It is now self-contained equipment for its asymmetrical reciprocating motion. This equipment is applied to nonferrous metals, ferrous metals and rare metals mineral, like gold, tungsten, tin, tantalum, iron, manganese, chrome, titanium, bismuth and lead whose size ranges from 2-0.037mm, also to pyrite whose size ranges from 4-0.037mm;Changing its grooves somehow, shaking table could be applied to some nonmetal mineral, like slack coal, coal slime, monazite, rutile etc, also to some mixed material which contains those with different specific gravities and sizes.

Double Deck Single Deck

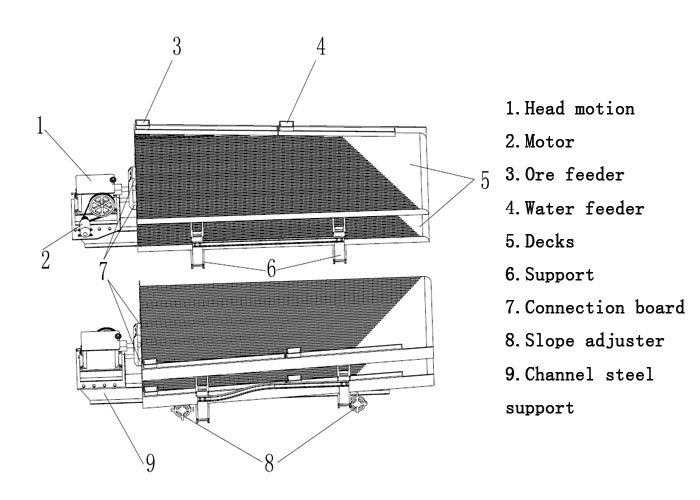

Structure of shaking table

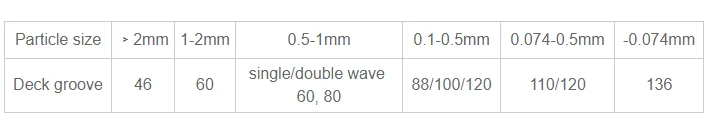

A. Deck of shaking table

Note: The above form is only for reference for the ordinary ore separation. The final selection of the deck type will depend on the actual ore situation,

separation flow, and so on.

B. Types of shaking table

There are left-hand type and righthand type shaking table depending on the different feeding position. Standing at the head motion side,

looking at the concentrates discharge side, if the feeding chute is on the left hand, it is the left-hand type. If the feeding chute is on the right

hand, then it is the right-hand type.

C. Support of shaking table

There are mainly 3 kinds of supports available (Customized channel steel support is available):

1) Ordinary cement foundation support (customer pouring the cement foundation themselves)

2) #10 channel steel support

3) #28 channel steel support

Working Principle of shaking table

The working principle of shaking table is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove) to allow loose layering of ores on the bed surface and fan-shaped zoning. Then different products can be produced.

Advantages of shaking table

1) Smaller floor area. That could reduce the cost on the construction area of the plant.

2) Lower energy consumption. The power of the double-layer shaking table is 0.7kw lower than that of 2 sets of single layer shaking table, which saves the cost on the power consumption.

3) A larger capacity. Capacity of one double-layer shaking table is 2 times of that of asingle layer shaking table, which could reduce your investment.

4) High cost-performance. The double-layer shaking table has a much favorable price than 2 sets of single layer shaking table.

5) Lower labor cost. In the condition of same quantity of shaking tables, the double layer type only take half operators of that of one single layer shaking table.

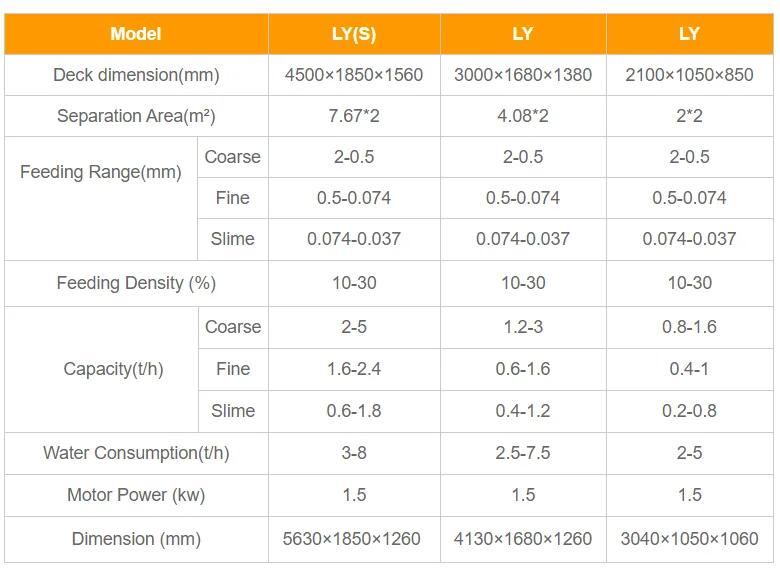

Technical Specification of shaking table

Application of shaking table

Contact us

Name: Helen Huang

Skype: sabrina88196

Tel: 0086-15879777833

Email: helen@perrymining.com

- Previous:JT Jig

- Next:6S Shaking Table