Fully Auto Centrifugal Concentrator

Centrifugal Concentrator

>> Ore discharge automatic, discharge fast.

>> Adjustable G-force value can be realized.

>> High concentrating ratio and recovery

>> Fully automatic running by configuring PLC system

>> Low water and electricity requirements

Description of centrifugal concentrator

Jinshibao is a family of mineral processing products specifically designed to recover fine precious metals including Gold, Silver and Platinum. The product line includes concentrators, slurry pumps, vibrating screens and modular plants.

D series centrifugal concentrator was designed by the professional mineral processing engineers, which is a Knelson-like concentrators. D series centrifugal concentrator has all the quality, reliability and performance you would expect from the top goods MADE IN CHINA. Now it's fully automatically washing, which requires nobody to discharge the ore.

HARD ROCK GOLD MINING EQUIPMENT

-

Initial Processing of Hard Rock Ores

-

Re-Processing of Hard Rock

-

Concentration of Ores for Regional Processing

ALLUVIAL AND DREDGING

-

Primary Process when you know your Gold is too fine for a sluice

-

Daily Upgrading of Sluice Concentrates

ENVIRONMENTAL REMEDIATION

-

Recovery of Mercury from Tails

HARD ROCK GOLD MINING APPLICATIONS

Hard Rock miners around the world have historically recovered as little as 30% of their free gold using mercury amalgamation. The Jinshibao process is being used to scavenge/reprocess old tails without using mercury. These miners are now recovering more gold reprocessing tails with Jinshibao than the original miners recovered. They are also recovering significant quantities of Mercury.

Hard rock miners must first understand some definitions:

-

Free Gold has been liberated and depending on its size will be visible in a pan.

-

Free Milling Gold is the gold that can be liberated by a standard rotating ball mill or other locally available milling methods.

-

Refractory Gold is that which is not recoverable by standard milling and/or leaching processes. This may be ‘entrapped in sulfides.’ A standard ball mill may grind your ore to 75 microns.

-

Gravity Recoverable Gold (GRG) refers to how much gold you can recover based on how fine you are grinding/milling your ore.

The GRG (Gravity Recovery Gold) testing is available.

The number 1 application for D series centrifugal concentrator is Hard Rock. The 50-80 TPH capacity and the ability to recover fine, flat milled gold are ideal for D series centrifugal concentrator. The major mines of the world use gravity concentration in their grinding circuits. The concentrators can recover over 90% of the overall production of major/professional mines.

A typical Hard Rock application would involve a crusher and ball mill. The material would be size classified using a cyclone in closed-circuit or simply a screen in semi-closed circuit milling. After the mill the material will pass through the concentrator. The major mines have a ‘recyclic load.’ Their processes are designed for the feed to pass through a concentrator multiple times before passing to the tails.

A Hard Rock operator may choose to run 25 tons per hour of a high grade ore. He may choose to rinse the bowl every 3 hours. Here, he would have run 75 tons in 180 minutes and collected 40-80 kg of concentrate. That is a concentration ratio of 1000 to 1.

The concentrate will still need to be upgraded or cleaned to have a sellable product. Some miners around the world are choosing to collect the concentrates from multiple mine sites and clean the cons at a regional secure facility. This is known as ‘pre-concentration’.

When scavenging old tails the operator must understand that there is a reason the first miner missed this gold. It may be that it was poorly milled and needs to be re-milled to liberate more gold. In order to recover what another team missed the operator must pay attention to the details and be prepared to adjust their process as required. To understand your ore and how much gold you can expect to recover, IGR recommends testing your samples at lab.

ALLUVIAL/PLACER

The D-series is impacting the world of Alluvial Mining.

Alluvial miners often ignore the fine gold because sluices and jigs can’t catch it. Depending on the size and shape of your gold a sluice may begin to lose gold at 40 mesh. Some alluvial deposits have 90% of their gold finer than this. This is where enhanced gravity, D-series, is one of the solution.

Concentrators are being tested on the ends of sluices. In this case the operation is still capturing the same amount of gold in the sluice. The added value of the concentrator becomes very clear.

After seeing the additional recovery of the concentrator some operators are choosing to redesign their process. An efficient plant design would include a screen (typically 2mm or 10 mesh) where only the coarse material will be routed to a sluice and only the fine material will be routed to your concentrator.

Features that make Jinshibao Centrifugal Concentrators ideal for small scale applications include:

-

Low machine weight

-

Ease of Installation

-

Only one moving part

-

Use of wear components readily available in developing areas

-

Rigid structure conducive to running at high speeds

-

Low acquisition and operating costs

-

A proven, robust and simple mechanical/electrical platform

-

Efficient clean out

-

High concentration ratios

-

All D-series products include a VFD/Soft Start

-

Value priced well below the competition

-

Simple push button start/stop

HOW IT WORKS

The D-series Concentrator is designed to capture all heavy minerals including Gold, Silver and PGMs and Mercury. It uses enhanced gravity to concentrate very fine, free minerals that are not recoverable using the traditional techniques of small scale and artisanal miners. The technology is based on the batch-type Knelson concentrator.

In operation, material is fed as a slurry of minerals and water into a rotating bowl that includes special fluidized grooves or riffles to capture the heavies. Periodically, a rich concentrate is rinsed out and requires further upgrading to be turned into a final gold product.

GENERAL COMMENTS ON MINERAL PROCESSING

Throughout history gold processing has been plagued with inefficiency and contamination. Millions of dollars of fine gold have been discarded in the tails or “washed down the creek” due to inadequate processing. Other operations have long put the health of both workers, and our planet at risk with the use of mercury, cyanide and other dangerous chemicals. Jinshibao technology successfully addresses both issues, ensuring that the highest percentage of gold is recovered and no hazardous chemicals are needed.

The most important factor in mineral processing is classification; the relative size of the gold you are processing must be known. Mineral processing is expensive and time consuming. Processing large material that is known to have no value, costs both money and time. With classification, time, energy and money will not be wasted processing excess material that is known to have no values. For example, if you know that your largest gold is .5mm then there is no reason to put 10mm material through your process. Also, the large feed will affect the efficiency of any process. The large material will hinder the recovery of the finer materials. For example, one miner improved his recovery from 40% to 70% simply by screening his feed from 8mm to 2mm. No gold was lost, because his largest gold was around 0.5mm. The Jinshibao method will improve your process by screening your feed to the proper size (reducing the volume of feed) and increasing the percentage of gold that you recover.

Power Generator Recommendations

For the reliability of your generator we recommend that your generator has double the capacity required by your equipment. For connection to line power, only the actual power consumption is needed.

Clean Water Connection

The user will have to supply clean pressurized water to the concentrator. Connect your clean pressurized water supply to the hose barb on the plumbing manifold on the concentrator.

It is important to use the same size hose as the barb to supply this process water. A smaller hose, long hose or hose with bends/restriction will restrict the water flow and limit the pressure to the concentrator.

The process water should be fed from a dedicated supply line and pump. Connection to a manifold where other people may be using this same supply may cause wild fluctuation in the pressure and lead to unpredictable gold recovery.

The water does not have to be perfectly clean. Murky water is acceptable. The water should be clean enough to pass a 50 mesh screen.

Performance of centrifugal concentrator

This is a STBL60 centrifugal concentrator. You could tell the naked alluvial gold.

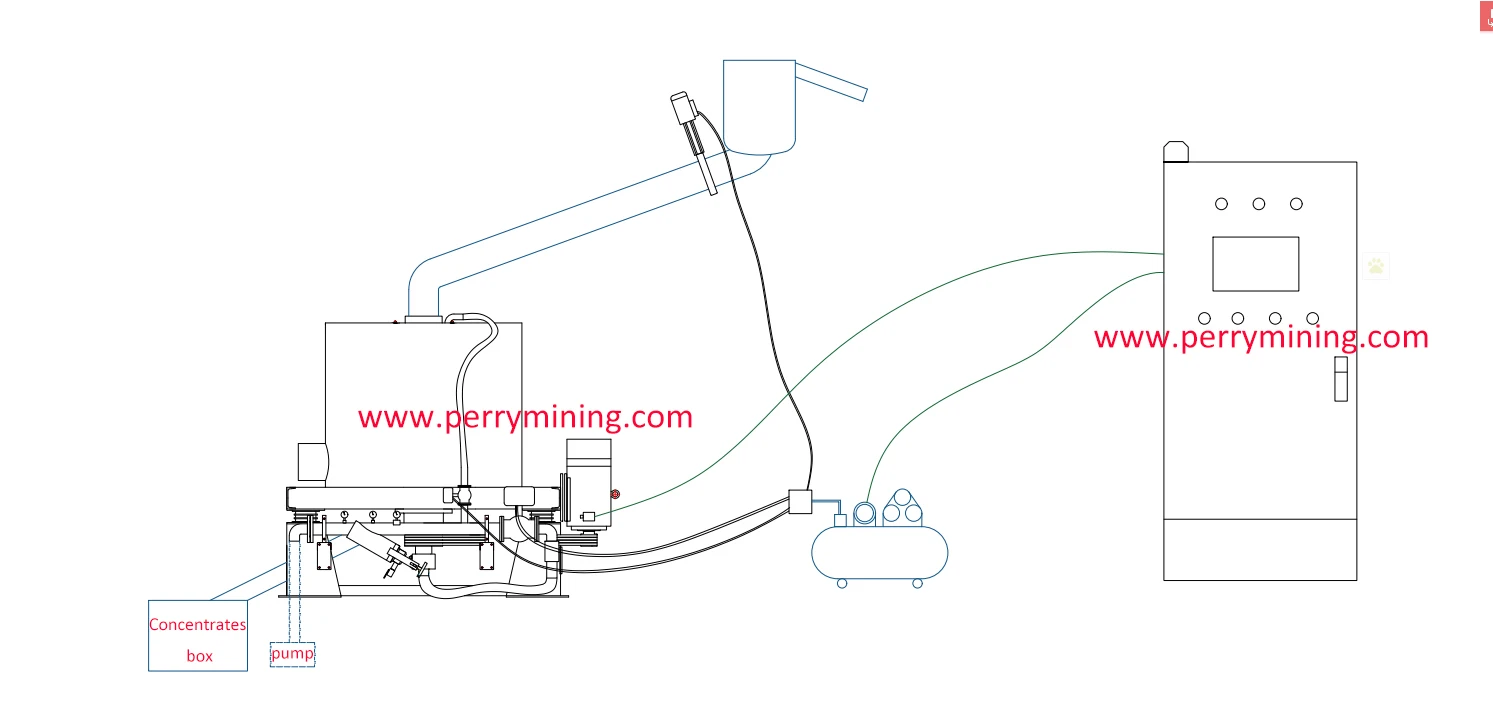

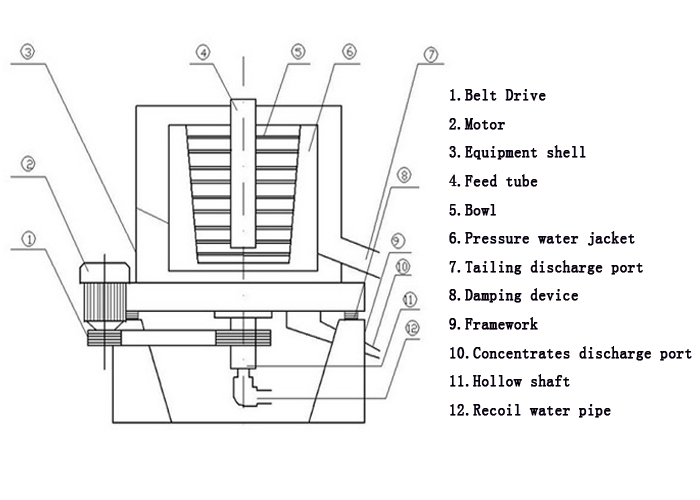

Structure of centrifugal concentrator

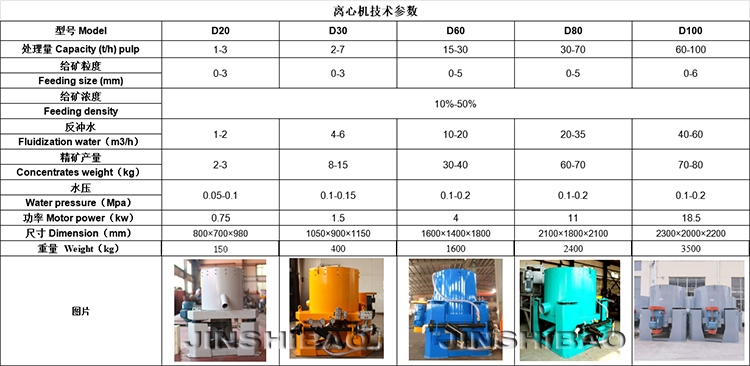

Technical Specification

o

centrifugal concentrator

Application of centrifugal concentrator

- Previous:Spiral Chute

- Next:JT Jig