GXD series centrifugal concentrator

GTD Series Centrifugal Concentrator

Click here to watch the video on Youtube

>> Ore discharge automatic, discharge fast.

>> High concentrating ratio and recovery

>> Fully automatic running

>> Low water and electricity requirements

>> PLC automatic system

>> With different G-force separation

General Introduction

The centrifugal concentrator is the most widely utilised centrifugal gravity concentration device in the industry.

It combine centrifuge enhanced gravitational force with a bed fluidization process to provide unmatched performance in the recovery of precious metals such as gold and fine gold, platinum, silver, mercury and native copper.

The centrifugal concentrator relies on an enhanced gravitational force together with fluidization process to recover even very micron sized particles. First water is injected into the rotating concentrating cone through series of fluidization holes. Then feed slurry is introduced through a stationary feed tube. Once the slurry is filled in each cone, create a concentrating bed and high specific gravity particles are retained in the cone and then flushed into the concentrate launders. This procedure can be completed in less than one minute.

60G-120G G-force are adjustable on our concentrator. The centrifugal concentrator uses 60G G-force in standard which is mainly suitable for the alluvial gold and released granular gold after ball mill grinding; the G-force at 90G and above are mainly suitable for the wrapped gold which is unable to be fully released by grinding, non-ferrous metals with less specific gravity, or the tailings process in the flow.

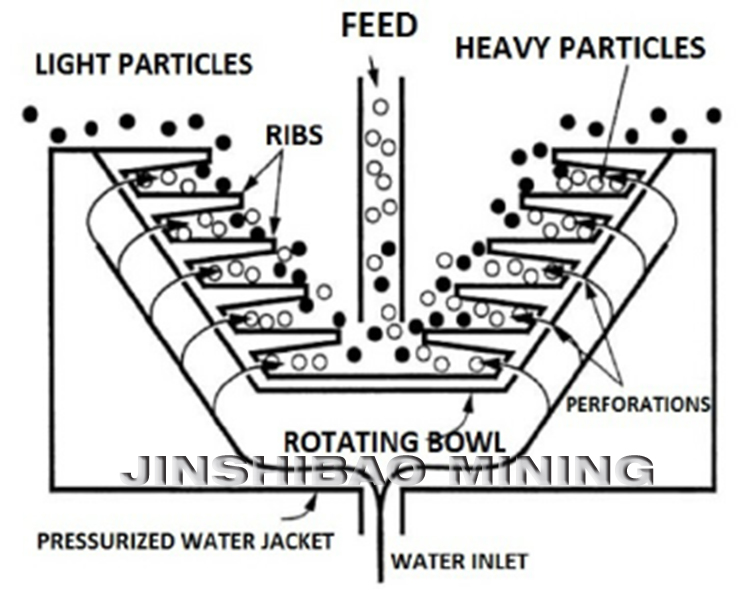

Working principle

Essentially all the models consist of a conical inner shell, with a series of parallel “vee” shaped riffles, bolted to a rotating outer shell. Feed is introduced in the form of slurry at the bottom of the unit through a central tube. A theoretical centrifugal force of around 60G causes the feed solids to fill the inter-riffle spaces from bottom to top. Once these spaces are full of solids the introduction of further feed starts the sorting stages where heavy minerals displace the lighter minerals and as a result the heavy minerals are trapped in the inter-riffle spaces while the lighter minerals are carried by water to the top of the unit, hence a separation occurs. To keep the bed of heavy minerals thus formed fluidised. water is introduced through the multiple fluidisation holes in the inner shell. This fluidisation water force is expected to be strong enough to inhibit severe compaction of the heavy mineral bed due to the strong centrifugal force. The concentration mechanism in the centrifugal concentrator may thus be linked to a hindered settling classifier.

Currently there are mainly 2 models available for industrial application, GXD-80 and GXD-50. The capacity below mentioned are both the dry ore capacity.

Here are some photos of the GXD series centrifugal concentrator:

- Previous:50tph Alluvial Gold Process Line

- Next:CT Magnetic Separator