JT Jig

Saw-tooth Wave JT Jig Machine

>> A new generation gravity concentration equipment

>> Saw-tooth wave shaped pulsation curve which is better for the efficient concentration

>> Applicable for feeding size as large as 60mm

>> Energy-saving & Environmental-friendly

>> Large capacity & High recovery

Description

Jig concentrators are devices used mainly in the mining industry for mineral processing, to separate particles within the ore body, based on their specific gravity (relative density). The particles would usually be of a similar size, often crushed and screened prior to being fed over the jig bed. There are many variations in design; however the basic principles are constant: The particles are introduced to the jig bed (usually a screen) where they are thrust upward by a pulsing water column or body, resulting in the particles being suspended within the water. As the pulse dissipates, the water level returns to its lower starting position and the particles once again settle on the jig bed. As the particles are exposed to gravitational energy whilst in suspension within the water, those with a higher specific gravity (density) settle faster than those with a lower count, resulting in a concentration of material with higher density at the bottom, on the jig bed. The particles are now concentrated according to density and can be extracted from the jig bed separately. In the mining of most heavy minerals, the denser material would be the desired mineral and the rest would be discarded as floats (or tailings). There are some minerals, notably coal, that are lighter (lower in density) than the surrounding rock and in such instances the process of extraction would work in reverse, i.e. the coal would settle on top with the rock below (on the jig bed). There are several designs and methods of extraction from the jig bed.

Structure

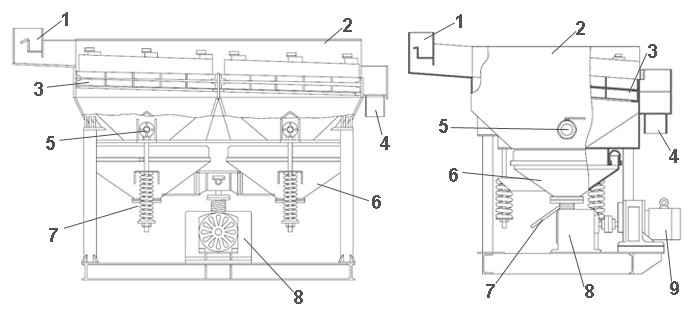

The sawtooth wave jig machine is mainly consist of jigging chamber, rubber diaphragm, cone, uppper-screen discharging device, electromagnetic adjustable speed motor, cam box, supplemental water pipe flange, screen, and feeding chute. The cam box is made of cast iron.

1. Feeding chute 2. Jigging chamber 3. Screen 4. Tailing outlet 5. Recoil water flange 6. Cone

7. Concentrates outlet 8. Cam box 9. Electromagnetic adjustable-speed motor

Working Principle

The jig machine is an open tank filled with water and a thick layering of bed stones, called ragging, supported on a horizontal perforated surface as below.

The water is pulsated up and down (i.e. the jigging action) pneumatically or with the use of a mechanical plunger .

The jigging action causes denser particles to preferentially trickle down faster and are removed from the bottom of the unit.

Technical Specification

Our improved model JT2-2 jig machine is widely applied on mining vessels for roughing, scavenging, and cleaning concentration of gold ore.

The max. feeding size of our improved models JT4-2 and JT5-2 could be up to 60mm by adopting the upper-screen discharging device. So it can be applied for mineral separation with large particle sizes, such as barite, manganese, iron, etc.

Application

Contact Us

|

Name: Sabrina Huang

|

|

Skype: sabrina88196

|

|

|

Tel: 0086-15879777833

|

|

|

Email: jinshibaosabrina@shakingtable.com.cn |

- Previous:Fully Auto Centrifugal Concentrator

- Next:2-Deck Shaking Table