Mercury Distill Retort

Mercury Distill Retort

Mercury Distill Retort is widely used in small gold mining plant for evaporation the Hg from the Hg+ gold mixture, and refining

the pure gold.

Description

Mercury Distill Retort is widely used in small gold mining plant for evaporation the Hg from the Hg+ gold mixture, and refining

the pure gold.

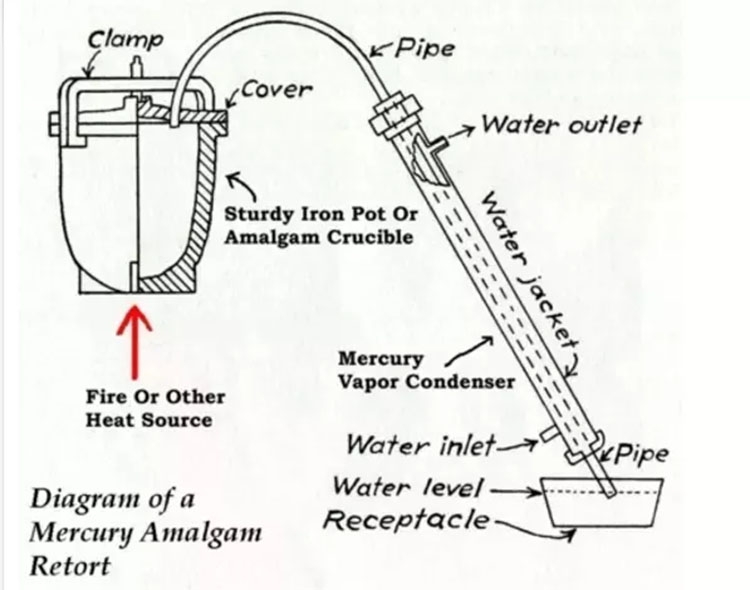

Operation principle

1. Put the Mercury Distill Retort mix with gold into the sealed cast iron tins. There is a condenser tube connected with the top of the iron can.

2. Heat the steel can on the Coke, gas or electric furnace

3. When the temperature reached 356°C, the amalgam will gasification, the mercury gas will run out through the stainless steel tube

4. The gas mercury will become Spherical droplets after go through the condenser tube, and then you can recycle the mercury.

5. In order to separate the mercury completely, gold mining plant usually maintained the temperature on 400-450°C. And in the last 30 minutes, raised the temperature to 750-800°C.

6. Distill the mercury for around 5-6hours, the gold recovery rate can reach 99%.

Note: In the whole process of mercury evaporation, the operator must wear a mask to avoid damage to the human body.

|

Weight |

6kg |

|

Warranty of core components |

6 months |

|

Usage |

Separate gold from mercury |

|

Material |

stainless steel |

|

Capacity |

10-15kg/time |

Follow Us in LinkedIn

Follow Us in Youtube

Follow Us in Facebook

Address: No.9 Industrial Avenue of Guzhang Industrial Park, Shicheng County, Ganzhou City, Jiangxi Province, China

Tel:+86-797-5793186 Fax:+86-797-5793558 mobile phone:+86-13870712983

赣公网安备36073502000186

赣公网安备36073502000186