Slurry Pump

Slurry Pump

<< The M.AH.HH dregs thick liquid pumps for the bracket

<< Is the horizontal-type gentrifugalism dregs thick liquid pumps.

<< Is suitable to industry sector and so on the metallurgy, mine, coal, electric power, building materials transports the strong abrasion

<< The highly concentrate dregs thick liquid.

<< Most important parts in the mining process

Description

The slurry pump is very important for mining process, to transport the material pulp on the mining separation machines. The slurry pump have the vertical and horizontal type, that is depending on the water resource place. The slurry pump is certifugal type ,and it can transfer the material with acid and normal mixture.

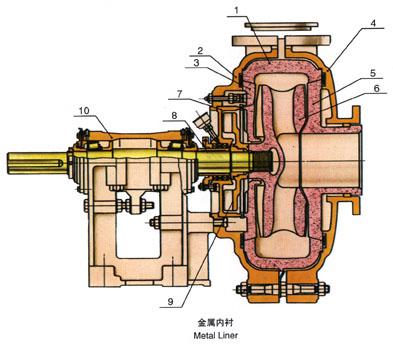

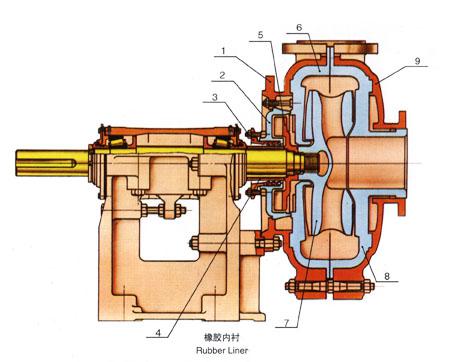

Structure

1、protective covering 2. pump bodies behind 3. Protect the board 4.water pumps covers front 5. To protect the board

6. Impellers 7. Toreduce the gland 8. Axle sleeves 9. Impellers 10. Bearings modules

1. Pump bodies 2. Reduce the gland 3. Padding glands 4. Axle sleeves 5. Impellers

6. Latter protective covering 7. Impellers 8. Front protective covering 9. Water pumps covers

Working Principle

The main working parts that is the impellers, the impeller installed in the axle, to be the complete one with motor. When the motor is driven the impellers, the impellers will impact the material pulp, after that increase the press energy and motion energy. Under inertia and with high pressure, the material pulp will through the pipe to discharge. The slurry pump can achieve to do 24 hours operation continuity workings.

Technical Specification

Model

Outlet Dia.

Speed

Main technical parameters

Power

Impeller Dia.

Flow

Lift

Efficiency

1.5/1B-AH(R)

25

1200~3800

10.8~28.8

6~68

40

15

152

1.5/1C-HH

25

1400~2200

16.2~34.2

25~92

20

30

330

2/1.5B-AH(R)

37

1000~3200

25.2~72

5.5~58

50

15

178~184

3/2C-AH(R)

50

1300~2700

36~86.4

12~64

55

30

214

3/2D-HH

50

850~1400

68~136

25~87

47

60

457

4/3C-AH(R)

75

800~2200

79~198

22~55

71

30

245

4/3D-AH(R)

75

800~2200

79~198

22~55

71

60

245

6/4D-AH(R)

100

600~1600

126~396

7~64

65

60

365

8/6E-AH(R)

150

400~1140

288~828

5~70

70

120

510

Application

Contact me

Contact Name :

Shelly Huang

Email Address :

shakingtable@shakingtable.com.cn

Skype :

jxscjsb

Mobile phone :

+8615879775031

Whatsapp :

+8615970857791

- Previous:Back

- Next:Water Pump