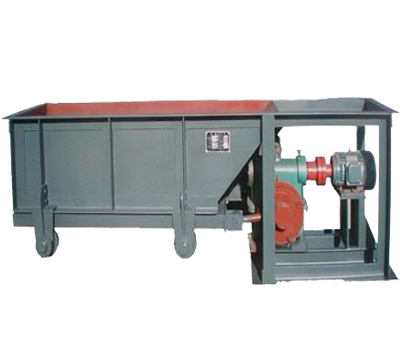

Chute Feeder

Chute Feeder

>> Simple structure, easy operation, convenient installation and adjustment.

>> Large capacity, high efficiency, less power consumption.

>> Stable vibrating, reliable performance and long working life.

Description

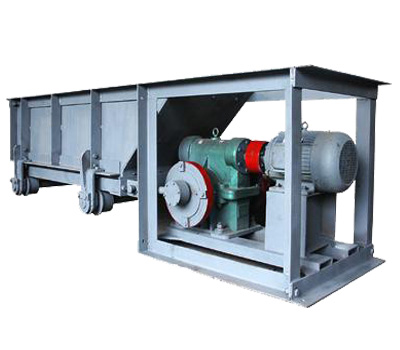

ZGC series chute feeder, feeding massive and granular materials from the storage bunker to various equipment, is widely used in the industries of the metallurgy, mining, chemical, construction, coal and so on.

The chute feeder can not only be installed on the ground, but also be hoisted at the bottom of the ore bin outlet. The chute bottom plate moves reciprocating motion whose frequency is 20-60rpm and stroke is 20-200mm

The tank width of chute feeder is about 2-2.5 times of the max particle size of the feeding material. The largest model size could meet the requirement to feed ores as large as 500mm. The most popular model size is ZGC-980*1240 which is quite suitable for feeding for PE400*600 jaw crusher.

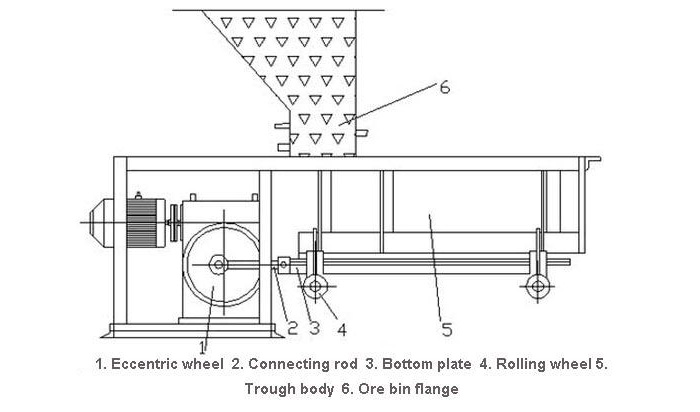

Structure

Working Principle

Minerals fall on the bushing. The bushing is located at the chute bottom, configured on idler wheel and via eccentric device connected with reducer which is linked to electric motor by coupler. When it works, electric motor drives reducer via coupler; eccentric disk and drain cap which is situated between chute frame bottom and roller begin to do reciprocal and linear motion so as to uniformly feed minerals.

Technical Specification

|

Model |

Motor |

Feeding Size (mm) |

Stroke (mm) |

Capacity (t/h) |

Dimension (mm) |

Weight (t) |

|

|

Model |

Power (kw) |

||||||

|

400×400 |

Y90L-6 |

1.1 |

100 |

- |

2.5-3 |

2350×725×625 |

0.64 |

|

600×500 |

Y112M-4 |

4 |

200 |

0-50 |

10-50 |

2750×910×855 |

1.054 |

|

980×1240 |

Y132M-4 |

7.5 |

350 |

25-75 |

20.7-69 |

3105×1280×1175 |

1.676 |

Contact Us

|

Name: Sabrina Huang

|

|

Skype: sabrina88196

|

|

|

Tel: 0086-15879777833

|

|

|

Email: jinshibaosabrina@shakingtable.com.cn |

- Previous:Swaying Feeder

- Next:Leaching Tank