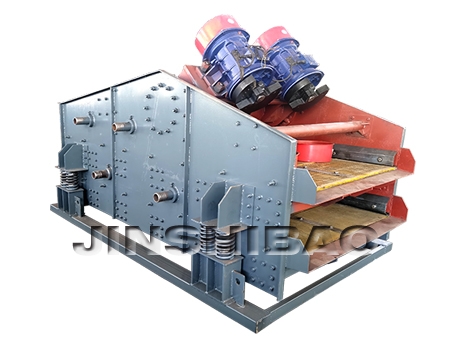

ZK Linear Vibrating Screen

ZK Linear Vibrating Screen

1. Large processing capacity, high structural strength, sturdy and durable, and easy maintenance.

2. Low energy consumption, low noise and long service life of polyurethane screen.

3. High screening precision, adjustable particle size and high screening efficiency.

4. Good dehydration effect, safe and reliable.

Description

ZK Linear Vibrating screen is named after the movement trajectory of the screen box is a directional straight line. It is widely used in mines, quarries, environmental protection, transportation and other departments for dry and wet screening and classification or dehydration, desliming, and deintermediation of various medium and fine materials.

Through years of practice, it has been proved that this series of vibrating screen has large processing capacity, reasonable technical parameters, high structural strength, stable operation, low noise, convenient maintenance and repair, and is highly praised by users.

Operating Principle

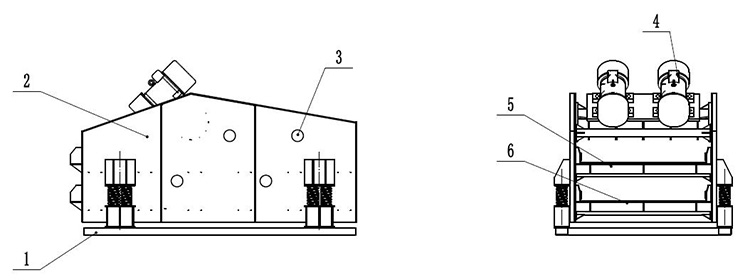

1. The two eccentric shafts of the ZK linear vibrating screen vibrator are equipped with equal eccentric masses with the same eccentric distance to ensure sufficient vibration frequency of the screen body. The two-axis motion adopts dual-motor automatic synchronization technology, and the two-axis rotation directions and opposite speeds are equal. The material on the screen surface moves forward, and is also compacted during the jumping and falling process. Therefore, it is especially suitable for dehydration, desliming, deliquoring, and removal of heavy medium in beneficiation of heavy medium.

2. The connection between the motor and the eccentric shaft of the exciter adopts a saddle block elastic coupling, which has the advantages of large bearing torque and good winding performance.

1. Bottom frame 2. Screen box 3. Spray system 4. Vibration motor 5. Upper screen 6. Lower screen

Specification

|

Model |

cover surface/m2 |

mesh aperture |

Input size/mm |

Capacity t/h |

double-amplitude(mm) |

shake frequency (r/min) |

Motor |

|

|

ZK-1236 |

1.2*3.6 |

0.5-13 |

≤100 |

10-30 |

6-8 |

960 |

Y130M2-6 |

2*5.5 |

|

ZK-1436 |

1.4*3.6 |

0.5-13 |

≤100 |

25-45 |

6-8 |

960 |

Y130M2-6 |

2*5.5 |

|

ZK-1536 |

1.5*3.6 |

0.5-13 |

≤100 |

35-55 |

6-8 |

960 |

Y130M2-6 |

2*5.5 |

|

ZK-1545 |

1.5*4.5 |

0.5-13 |

≤100 |

40-70 |

6-8 |

960 |

Y160M-6 |

2*7.5 |

|

ZK-1861 |

1.8*6.0 |

0.5-13 |

≤100 |

70-110 |

6-8 |

960 |

Y160L-6 |

2*11 |

|

ZK-2148 |

2.1*4.8 |

0.5-13 |

≤100 |

65-100 |

6-8 |

960 |

Y180L-6 |

2*15 |

|

ZK-2448 |

2.4*4.8 |

0.5-13 |

≤100 |

75-115 |

6-8 |

960 |

Y180L-6 |

2*15 |

|

ZK-2161 |

2.1*6.1 |

0.5-13 |

≤100 |

90-150 |

6-8 |

960 |

Y200L-6 |

2*18.5 |

|

2ZK-2161 |

2*2.1*6.1 |

3-50 0.5-13 |

≤300 |

90-150 |

6-8 |

960 |

Y200L-6 |

2*18.5 |

|

ZK-2461 |

2.4*6.1 |

0.5-50 |

≤100 |

95-170 |

6-8 |

960 |

Y200L-6 |

2*18.5 |

|

2ZK-2461 |

2*2.4*6.1 |

3-50 0.5-13 |

≤300 |

95-170 |

6-8 |

960 |

Y200L1-6 |

2*18.5 |

|

ZK-3061 |

3.0*6.1 |

0.5-13 |

≤100 |

120-185 |

6-8 |

960 |

Y200L2-6 |

2*22 |

|

2ZK-3061 |

2*3.0*6.1 |

3-50 0.5-13 |

≤300 |

120-185 |

6-8 |

960 |

Y225M-6 |

2*30 |

|

ZK-3661 |

3.6*6.1 |

0.5-13 |

≤100 |

140-220 |

6-8 |

960 |

Y225M-6 |

2*30 |

|

2ZK-3661 |

2*3.6*6.1 |

3-50 0.5-13 |

≤300 |

140-220 |

6-8 |

960 |

Y250M-6 |

2*37 |

|

ZK-3673 |

3.6*7.3 |

0.5-13 |

≤100 |

170-260 |

6-8 |

960 |

Y250M-6 |

2*37 |

Application

- Previous:Bucket-wheel Sand Washing Machine

- Next:Gold Pan