Bucket-wheel Sand Washing Machine

Bucket-wheel Sand Washing Machine

Bucket-wheel sand washing machine has high washing degrees, reasonable structure, large processing volume, small power consumption, and less sand loss during sand washing, especially the sand washing machine transmission part is isolated from water and sand, so its failure rate is greatly low. Sand washing machines are currently commonly used.

Description

The Bucket-wheel sand washing machine has high washing degrees, reasonable structure, large processing volume, small power consumption, and less sand loss during sand washing, especially the sand washing machine transmission part is isolated from water and sand, so its failure rate is greatly low. Sand washing machines are currently commonly used.

Rotor sand washing machines are widely used in the selection, classification, removal of mixing, and miscellaneous materials in metallurgy, building materials, hydropower and other industries, and are suitable for the selection of fine -grained and coarse -size materials. It is still suitable for building sand and roads with sand. The sand washing machine has a reasonable structure, convenient maintenance, large processing volume, small power consumption, and high degree of washing. The novel sealing structure, fully closed oil bath transmission device, and adjustable overflow weir board ensure the efficient, durable, cleaning and dehydration effect of this series of products, good cleaning, dehydration, and stable fine -grained products.

Operating Principle

When the sand washing machine is working, the motor drives the impeller to slowly rotate through the triangle belt, reducer, and gear deceleration. The gravel is rolled into the groove of the groove from the groove. Impurities, at the same time, destroy the water -over -covered water, to facilitate dehydration; at the same time, add water to form a strong water flow, timely take away impurities and small foreign objects in time, and discharge from the overflow groove to complete the cleaning effect. The clean sand is taken away by the leaves. Finally, the gravel poured into the material tank from the rotating impeller to complete the cleaning effect of the gravel.

1. The engine is simple, the processing volume is large, the power consumption is small, and the washing degree is high.

2. Fighting sand washing machines are almost easy to lose parts except the sieve network. They have long life and do not need to be repaired for a long time.

3. The loss of fine sand and stone powder is very small.

4. This series of products is efficient and durable, clean, dehydrated, and not chaotic products.

Structure

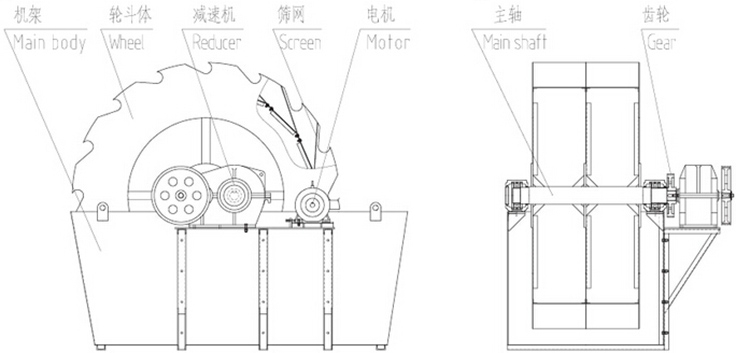

The main structural components of sand washing machines are: racks, wheel buckets, reducers, sieve nets, motors, spindles, gears and other main components.

Specification

Model

Wheel bucket size(mm)

Capacity(t/h)

Motor Power(kw)

Max Feeding size (mm)

Dimension(mm)

XSD2610

Φ2600*1000

20-50

5.5

≤10

3255*1982*2690

XSD2516

Φ2500*1600

40-80

11

≤10

3675*2400*2500

XSD2816

Φ2800*1600

50-90

11

≤10

3800*3000*2880

XSD3016

Φ3200*1600

60-100

15

≤10

3900*3000*3080

Application

- Previous:Spiral Sand Washer

- Next:ZK Linear Vibrating Screen