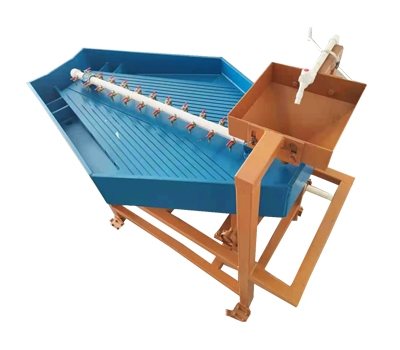

Product Show

Finishing Shaker Table

1. A finishing table to enable you to get the pure gold;

2. Lower cost with higher recovery;

3. Environment friendly, no mercury required

Product Description

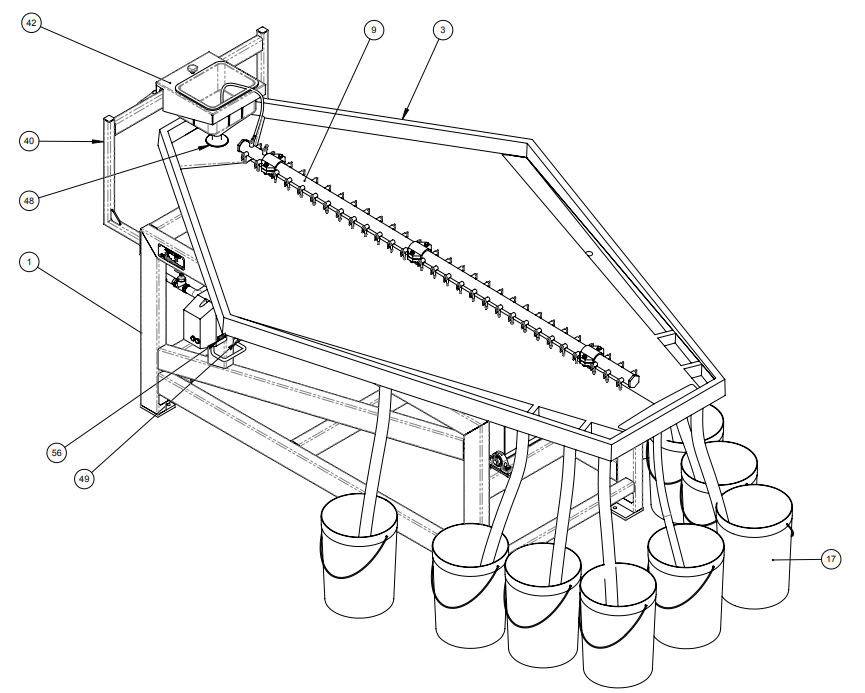

This finishing table has been specifically designed for the recovery of fine gold to a directly smeltable concentrate. Several models are available to cater for feed rates from 115 kg/h up to 450 kg/h. A laboratory unit is also available, treating 30kg/h.

The deck grooves are uniquely designed to optimize the collection of gold particles. The machine can be used to treat low-grade concentrates and still achieve high gold recoveries and grades.When deciding on the appropriate operation of the shaker table, the following factors need to be taken into consideration:

- Machine to be fed at constant feed rate

- Clean, constant pressure wash water is required for optimal separation

- The removal of fine iron particles (mill media etc) prior to the table using a READING low-intensity magnetic drum separator (LIMS) is recommended

Features

- Direct, fixed speed feed system

- The table can be operated in batch or continuous mode

- No massive foundation required

- Available for single or three-phase power supply

- Simple operation

- Adjustable feed rate

- Deck constructed of hard-wearing gel coat with GRP backing.

- Adjustable "bump stop" to control deck motion amplitude

- Recessed deck grooves for gold collection

- Multiple dressing water cock valves for wash water control

- Central water manifold constructed for resistance to attack by contaminated process water

Specifications

| Model | Capacity | Motor power | Dimension/mm | Weight/kg |

| GTC-60 |

30kg/hr |

0.55KW | 1490*894*1160 | 145 |

| GTC-250 |

115kg/hr |

1.1KW | 2180*1340*1350 | 220 |

| GTC-1000 | 500kg/hr | 1.5KW | 2800*1750*1365 | 320 |

- Previous:Back

- Next:4-layers Shaking Table