Diaphragm Jig

Diaphragm Jig

<< Simple operation, large capacity, and can obtain the final concentration or the tailing recovery.

<< Small space to install , suitable for the testing plant for minerals

Description

Diaphragm Jig has simple operation, large capacity, and can obtain the final concentration or the tailing in one beneficiation. So it is widely used in dealing with the coarse or medium-grained ore. It is suitable for classification the larger differential density of tungsten, tin, iron, manganese and chrome ore; also for ferrous metal and non-ferrous metals containing the gold and rare metals.

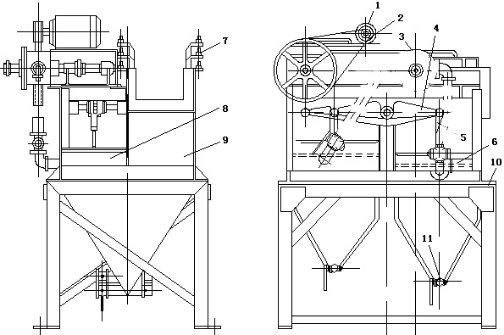

Structure

1 . Motor 2. Transmission sets 3. Separator 4. Rocker arm 5. Link 6. Rubber diaphragm

7. Feed chamber 8. Working chamber 9. Frame 10. Gape 11. Output port

Working Principle

There are two jig buckets with different sizes and each diaphragm is divided into jig area and diaphragm area by clapboard. The rubber diaphragm pumping to make medium (water) moving is the jigging course. The triangle belt drives big belt pulley by electric motor so connecting rod of the eccentric gear and rocker are up and down moving. Another connecting rod is connected with the rubber diaphragm which is moving up and down to jig .

Technical Specification

|

Model |

Chamber No |

Jig area m2 |

Feed Size mm |

Capacity t/h |

Stroke mm |

Frequency r/min |

Supply Water Rate t/h |

Water Pressure kg/cm |

Power kw |

|

100×150 |

1 |

0.15 |

-3 |

0.18-0.6 |

- |

420 |

- |

1-1.5 |

0.55 |

|

300×450 |

2 |

0.27 |

-12 |

3-6 |

0-26 |

322 |

2-4 |

1-1.5 |

1.1 |

|

1000×1000 |

2 |

2 |

1-5 |

10-25 |

0-26 |

200-350 |

60-80 |

0.6-2 |

1.5 |

|

370×360 |

2 |

0.26 |

6 |

1-3 |

5-25 |

200-250 |

2-5 |

- |

1.1 |

More details picture in factory

Contact Us

| Contact Name : | Shelly Huang |

| Email Address : | shakingtable@shakingtable.com.cn |

| Skype : | jxscjsb |

| Mobile phone : | +8615879775031 |

| Whatsapp : | +8615970857791 |