Trapezoidal Jig

Trapezoidal Jig

>> Simple operation and maintenance.

>> Water-recycling, High recovery, big capacity.

>> Energy-saving, high efficient, environmentally friendly.

>> Four jigging beneficiation slots, adjustable stroke, wide range of particle size.

Description

Trapezoidal jig has independent slots with its trapeziodal working sector, each slot can be adjusted independently.

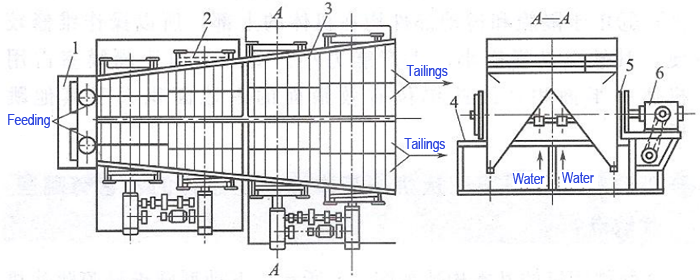

According to the diaphragm movement and the ore flow vertical movement, it is called lateral side moving diaphragm jig; according to jigging chamber surface shape is also called the trapezoidal jig.

Structure

The trapezoidal jig is composed of 8 jigging chambers, divided into two columns, each column 4 rooms, each room of the stroke speed

can be adjusted separately; 2 columns of the jig 1-4 rooms and 5-8 room with disconnecting device in the middle.

1.Feed launder 2. Counter-shaft 3.Screen plate 4.Frame 5.Diaphragm 6.Drive device

Working Principle

Trapezoidal jig cross section is trapezoidal, ore along the flow direction change from narrow to wide, slurry flow speed to be slow down in gradually, especially for fine grained heavy mineral to recovery. It takes advantage of water as medium, and separates according to density difference.

Technical Specification

Application

Trapezoidal jig is widely applied on the separation of gold, tin, tungsten, titanium, hematite, coal and other minerals.

And also used in the beneficiation of metals/ non-metals like limonite, specularite, manganese, antimony, fluorite, barite, celestite and so on.

Contact Us

Name: Helen Huang

Skype: sabrina88196

Tel: 0086-15879777833

Email: helen@perrymining.com

- Previous:Flotation Machine

- Next:Hydraulic Jig

Follow Us in LinkedIn

Follow Us in Youtube

Follow Us in Facebook

Address: No.9 Industrial Avenue of Guzhang Industrial Park, Shicheng County, Ganzhou City, Jiangxi Province, China

Tel:+86-797-5793186 Fax:+86-797-5793558 mobile phone:+86-13870712983

赣公网安备36073502000186

赣公网安备36073502000186