Cone Ball Mill

Cone Ball Mill

>> Stable operation, feeding and discharging controlled by motor.

>> Fast and convenient milling.

>> Well-distributed of the particle size.

>> Small over degree of grinding, high grinding efficiency.

>> Small power consumption.

Description

XMQ Series cone ball mill is a laboratory grinding equipment for wet grinding of ore and mineral analysis (150*50 cone ball mill also can be used for dry grinding).

It is applied in metallurgical, building material, chemical, coal, geological industries, etc.

It is also the supporting equipment for flotation machines and other equipment.

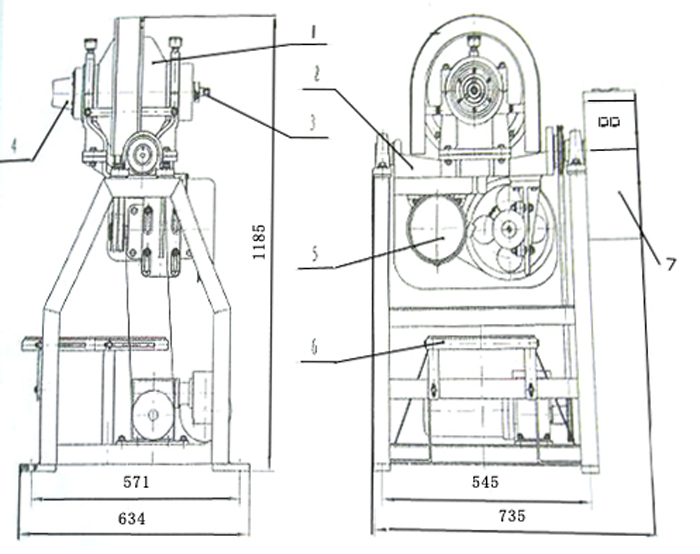

Structure

1.Left and right half shell 2.Supporting plate 3.Feeding port 4.Discharging port 5.Drive device 6.Collecting plate 7.Electric control cabinet.

Working principle

The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner, corrugated liner and steel balls with different in the chamber. The rotation of the barrel cause a centrifugal force to rise the steel balls at a certain height then fall to impact and grind the materials. After the coarse grinding in the 1st chamber, the material enter into the 2nd chamber for further grinding. The ground materials are discharged through discharging board.

Technical specification

|

Model |

XMQ150×50 |

XMQ240×90 |

XMQ350×160 |

|

Capacity(g) |

200 |

500~1000 |

4000 |

|

Feeding size(mm) |

-3 |

-3 |

-3 |

|

Output size(mm) |

-0.074 |

-0.074 |

-0.074 |

|

Power(kw) |

0.75 |

1.1 |

1.1 |

|

Dimension(mm) |

700*670*1160 |

700*670*1160 |

700*710*1300 |

|

Weight(kg) |

150 |

160 |

230 |

Contact us

Name: Helen Huang

Skype: sabrina88196

Tel: 0086-15879777833

Email: helen@perrymining.com

- Previous:Work Index Ball Mill

- Next:QHQM Lab Ball Mill