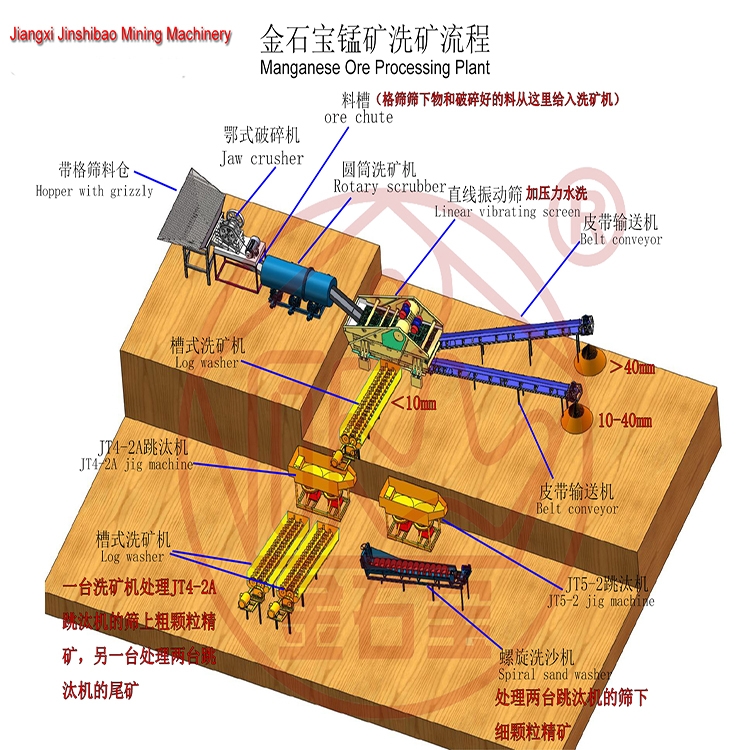

Manganese Ore Processing Plant

Manganese ore processing plant

Most manganese ore is a fine-grain, and contains phosphorus ore, iron ore and associated minerals, which brings a great difficulty to beneficiation processing. At present, the commonly used manganese ore beneficiation methods are mechanical beneficiation methods (washing, screening, gravity separation, strong magnetic separation and flotation), as well as special beneficiation methods (fire enrichment, chemical beneficiation, etc.)

The gravity separation solution : The raw ore is fed into the hopper via excavator, under the hopper, then use a jaw crusher to crush smaller size before trommel scrubber more evenly for washing the sticky clay. The feeding size to trommel scrubber is better controlled less than 100mm. After trommel scrubber ,the material will go on the double vibrating screen to screen the suitable size into the log washer to wash manganese ore again , under the screen, less than 10mm material size into first jig separator to get the coarse size manganese concentrate , the other jig separator can handle the first jig separator tailings . The spiral sand washer that will wash the fine size manganese concentrate under bottom of jig separator .

The gravity separation solution +strong magnetic separator

It will use the trommel scrubber or log washer to wash the sticky clay , and then go on the jig separator to get the coarse size concentrate,after then magnetic separator to remove the iron , to improve the manganese concentrate grade . Manganese mineral is a weak magnetic mineral, and it can be recovered in a strong magnetic field magnetic separator with a magnetic field strength (10000~20000GS), the manganese grade is increased by 4% to 10%.

Follow Us in LinkedIn

Follow Us in Youtube

Follow Us in Facebook

Address: No.9 Industrial Avenue of Guzhang Industrial Park, Shicheng County, Ganzhou City, Jiangxi Province, China

Tel:+86-797-5793186 Fax:+86-797-5793558 mobile phone:+86-13870712983

赣公网安备36073502000186

赣公网安备36073502000186